10 Essential Tips for Ordering Premixed Concrete Like a Pro

Ordering premixed concrete is an essential step for any construction project, whether you are laying the foundation for a home or creating infrastructure. According to a study by the American Concrete Institute, the concrete industry contributes about $100 billion annually to the U.S. economy, with premixed concrete accounting for a significant portion of this figure. This underscores not only the importance of concrete in construction but also the growing demand for efficient ordering processes that can ensure project success.

Industry expert Dr. Jane Holloway, a leading figure in concrete technology and author of multiple publications on concrete applications, emphasizes the importance of careful planning when she states, "To order premixed concrete effectively, one must consider not just the quantity, but also the specific requirements of the project, including mix design and delivery logistics." With her insights, it's clear that understanding how to order premixed concrete is crucial for obtaining high-quality material that meets project specifications and timelines.

As construction projects become more complex, the need for knowledgeable approaches to ordering premixed concrete has never been greater. By understanding essential tips and leveraging expertise, contractors and DIY enthusiasts alike can navigate this process like pros, ultimately contributing to the longevity and success of their projects.

Understanding the Basics of Premixed Concrete and Its Types

When it comes to ordering premixed concrete, understanding the different types available is crucial for making an informed decision. Premixed concrete is essentially a blend of cement, aggregates, and water that is mixed at a central facility before being delivered to the construction site. There are several standard types of premixed concrete, including ready-mix concrete, which is delivered in a liquid state, and self-consolidating concrete, known for its flowability and ability to fill forms without the need for mechanical vibration. Each type has its specific properties and applications, making it essential to choose the right one for your project needs.

Additionally, it’s important to consider the various additives that can enhance the performance of premixed concrete. For instance, water-reducing agents can improve workability without diluting the strength of the concrete, while air-entraining agents can enhance durability in freeze-thaw conditions. Understanding these types and their characteristics will not only help in selecting the appropriate product but also ensure that the concrete meets the required specifications for the job. Knowing these foundational elements empowers individuals to navigate the ordering process more confidently and effectively, ultimately leading to a successful construction project.

10 Essential Tips for Ordering Premixed Concrete Like a Pro

| Tip Number | Tip Description | Concrete Type | Recommended Usage |

|---|---|---|---|

| 1 | Know your project requirements | Ready-mix Concrete | General construction |

| 2 | Understand different concrete grades | High Strength Concrete | Structural applications |

| 3 | Consider local climate conditions | Cold Weather Concrete | Winter construction |

| 4 | Plan for the right delivery time | Standard Concrete | Routine projects |

| 5 | Calculate the exact quantity needed | Lightweight Concrete | Applications requiring lower weight |

| 6 | Communicate with your supplier | Pumpable Concrete | High-rise buildings |

| 7 | Check the mix consistency | Self-compacting Concrete | Complex forms and reinforcements |

| 8 | Review past project experiences | Architectural Concrete | Aesthetic projects |

| 9 | Understand curing requirements | High-Performance Concrete | Durability-focused projects |

| 10 | Consider eco-friendly options | Recycled Aggregate Concrete | Sustainable construction |

Identifying Your Project Requirements for Concrete Ordering

When ordering premixed concrete, the key to a successful project lies in accurately identifying your concrete requirements. Begin by assessing the specific needs of your project, including the type of structure you are constructing and the environmental conditions it will face. For instance, foundations, driveways, and decorative walkways all require different concrete strengths and finishes. Understanding whether your project demands high strength concrete or a standard mix is essential, as this will affect both durability and overall cost.

Once you have a clear grasp of your project size and type, consider additional specifications such as the required slump (workability), the inclusion of additives for specific properties, and curing requirements. It's crucial to calculate the volume of concrete needed; measures should be taken to account for factors such as waste and spillage.

Think about the timeframe for your project as well; ensuring that your concrete arrives on site when needed is vital for maintaining workflow and avoiding delays. By outlining these details meticulously, you position yourself to make informed decisions, ensuring the right mix is ordered and that your project runs smoothly.

Key Factors to Consider When Choosing a Concrete Supplier

When choosing a concrete supplier, it is crucial to evaluate several key factors that can significantly impact the quality and efficiency of your project. One of the primary considerations should be the supplier's reputation and experience in the industry. According to a report by the American Concrete Institute, approximately 75% of concrete failures can be traced back to material quality, which underscores the importance of selecting a supplier with a proven track record in providing high-quality premixed concrete. Look for suppliers with certifications from relevant bodies, as this often indicates adherence to industry standards and best practices.

Another critical factor is the supplier's ability to meet your specific project requirements, including the type of concrete mix and delivery times. Industry data suggests that the demand for customized concrete solutions has increased by 30% over the past five years, highlighting the necessity of finding a supplier that can offer tailored products. Additionally, logistics play a vital role in the timely delivery of concrete; thus, assessing the supplier’s delivery capabilities and fleet reliability can prevent costly project delays. A comprehensive understanding of these factors will ensure you choose a supplier that not only meets your concrete needs but also supports the overall success of your construction endeavors.

Tips for Accurately Calculating the Amount of Concrete Needed

When it comes to ordering premixed concrete, the first crucial step is accurately calculating the amount you need. This process begins with measuring the dimensions of the area where the concrete will be poured. Whether you're working on a patio, sidewalk, or foundation, taking precise measurements is key. Use a measuring tape to obtain the length, width, and depth of the area in feet. Always convert your measurements to a consistent unit to simplify your calculations. Remember that the thickness of your concrete layer can greatly affect the total volume required.

Once you have your measurements, you can apply the formula for volume: length multiplied by width multiplied by depth. This will give you the volume in cubic feet, which can then be converted to cubic yards (as concrete is often sold in this unit). To convert cubic feet to cubic yards, simply divide the cubic feet value by 27. Additionally, it’s wise to order a little extra concrete to account for spillage, over-excavation, or changes in your project requirements. A good rule of thumb is to add around 10% more than your calculated needs to ensure you don’t run short during the pour. With these calculations in hand, you can confidently place your order and ensure your project runs smoothly.

Concrete Volume Calculation: Essential Tips

Effective Communication with Concrete Suppliers for Best Results

Effective communication with concrete suppliers is crucial for obtaining high-quality premixed concrete that meets your project's specifications. Start by clearly defining your project requirements. This includes the type of concrete needed, the volume required, and any specific additives or features you want, such as air entrainment or rapid setting. Providing detailed information helps the supplier understand your needs and recommend the right mix that aligns with your project goals.

When interacting with your supplier, ask questions and be open to their suggestions. Experienced suppliers can offer valuable insights into material characteristics and delivery logistics that could influence your project's success. Be sure to communicate your timeline and any potential deadlines, as this will help the supplier manage their resources effectively to meet your schedule. Regular updates and discussions throughout the ordering process can also mitigate misunderstandings and ensure that the final product arrives on time and as expected.

Related Posts

-

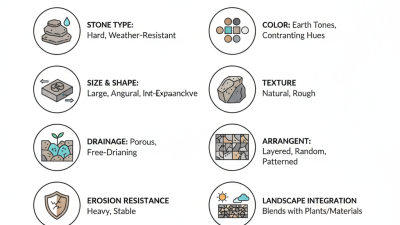

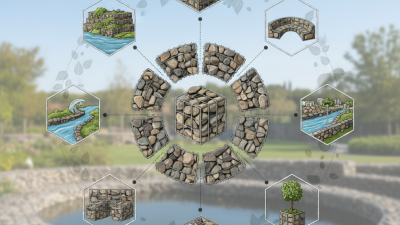

10 Tips for Choosing the Best Gabion Stone for Your Landscaping Project

-

2025 Guide: How to Use a Cement Needed Calculator for Your Projects

-

Top 2025 Uses for Gabion Stone: Benefits, Design Ideas, and Best Practices

-

What is Concrete Mesh? Essential Guide to Types and Benefits for Your Projects

-

Essential Tips for Getting Accurate Concrete Estimates for Your Project

-

Top 10 Benefits of Ordering Premixed Concrete for Your Construction Projects